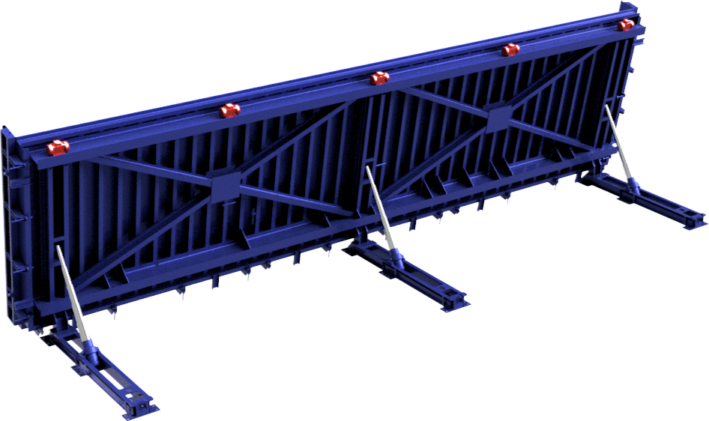

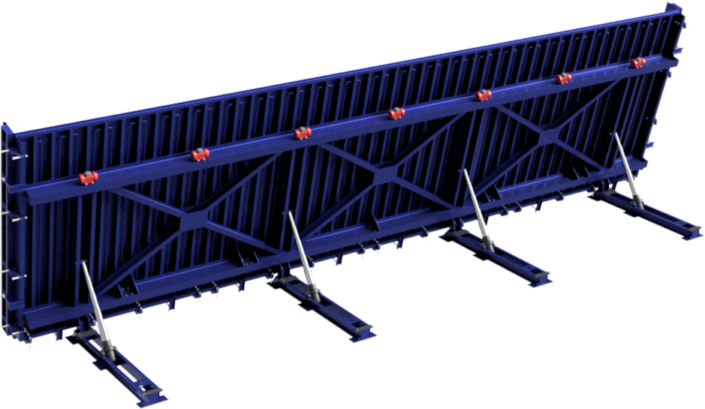

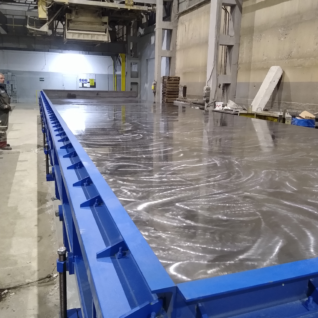

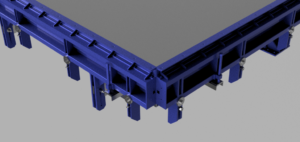

MAGNA tilting tables are a reliable solution for the production of flat concrete elements, providing all the essential features for precast concrete technology.

The maximum width of the tables that can be produced is up to 5.00 meters, allowing for the manufacturing of virtually all walls encountered in the market.

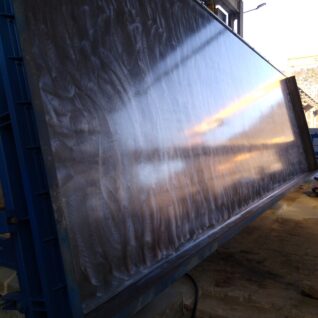

The lifting and lowering of the table are carried out by a hydraulic system with manual or radio-controlled operation

For:

- concrete walls

- concrete sandwich walls

- concrete slabs

- other flat concrete elements

Specification

- Side shuttering

- Control panel

- Vibration system

- Edge chamfering

- Heating system

- Extensions of surface

- Information

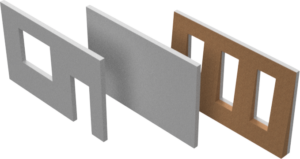

Side shuttering

- Shuttering fixed

two different options:

full shuttering fixed - there is no need for wooden framework

shuttering with channel sections - to fulfill with wooden framework

The height of the fixed side shuttering depends on the client's specifications

- Shuttering adjustable

The range of achievable adjustments extends from 100 to 400 mm height.

Formwork can have the ability to fold out for easier demolding and finishing of the element.

Control panel

The control of the table's hydraulics and vibration system can operated:

- wirelessly - remote control

- stationarily from the control panel

Vibration system

- In our constructions, we utilize high-frequency vibration system

6000/obr ̄1 100Hz 400V 2,4A ensuring optimal efficiency in the production of concrete elements on tilting tables

- Vibration system is optional

According to the client's requirements, the table does not need to be equipped with a vibration system, or it can be prepared for the installation of such a system in the future

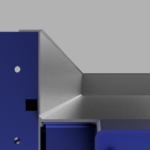

Edge chamfering

An additional feature of the table could be

- adjustable edge chamfering of the element - up and down

Heating system

- The installation of heating for the tilting table comprises a piping system

with the option of heating using either liquid or steam

- Heating system is optional

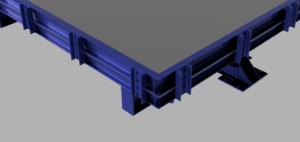

Extensions of surface

- Optional extensions for formwork magnets enable the utilization of the full width of the table for element production.

- The extension can allow for localized formwork of an element wider than the table's width.

Information

- max. load capacity during tilting 750 kg/m2

- max. load capacity without tilting 1000 kg/m2

- max. width 5,00 m

- max. length 16,00 m

- Thickness of the table covering 10 mm

- Accuracy of surface execution: 1.5 mm per 3,00 meters

- CE Certification

Implementations

We take pride in being one of the few Polish companies manufacturing large-scale forms for the production of precast concrete elements. It's our pleasure to support and advance the precast concrete industry in Poland. Collaborating with you allows us to embrace significant challenges, set new horizons, and forge a new chapter in the history of concrete

#MadeInPoland